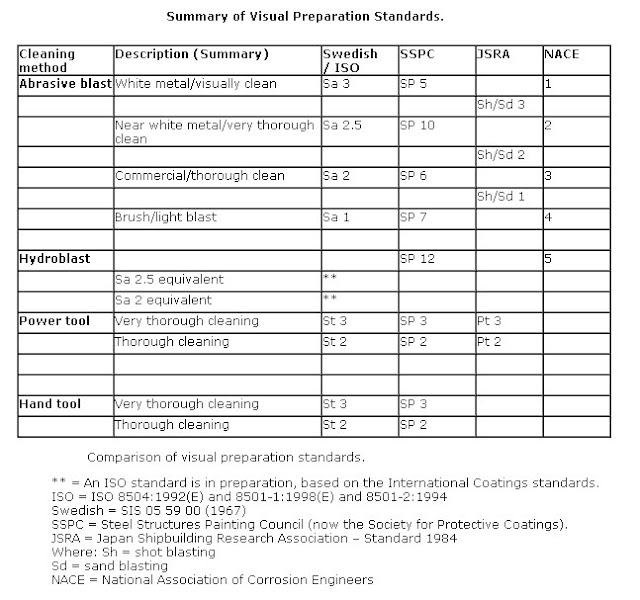

* NACE No. 1/SSPC-SP 5, White Metal Blast Cleaning

* NACE No. 2/SSPC-SP 10, Near-White Metal Blast Cleaning

* NACE No. 3/SSPC-SP 6, Commercial Blast Cleaning

* NACE No. 4/SSPC-SP 7, Brush-Off Blast Cleaning

* NACE No. 5/SSPC-SP 12, Surface Preparation and Cleaning of Metals by Waterjetting Prior to Recoating

* NACE No. 6/SSPC-SP 13, Surface Preparation of Concrete

* NACE No. 8/SSPC-SP 14, Industrial Blast Cleaning

Steel Structures Painting Council (SSPC)

• SP-1 Solvent Cleaning

• SP-2 Hand Tool Cleaning

• SP-3 Power Tool Cleaning

• SP-4 Flame Cleaning

• SP-5 White Metal Blast Cleaning

• SP-6 Commercial Blast Cleaning

• SP-7 Brush-Off Blast Cleaning

• SP-8 Pickling

• SP-9 Weathering Followed By Blast Cleaning

• SP-10 Near-White Blast Cleaning

Swedish Standard (St,Sa)

• St 2 Hand Tool Cleaning

• St 3 Power Tool Cleaning

• Sa 1 Brush-Off Blast Cleaning

• Sa 2 Commercial Blast Cleaning

• Sa 2 1/2 Near-White Blast Cleaning

• Sa 3 White Metal Blast Cleaning

EXPLANATIONS

SSPC-SP-1

Solvent Cleaning - Removal of all detrimental foreign matter such as oil, grease,

dirt, soil, salts, drawing and cutting compounds, and other contaminants from

steel surfaces by the use of solvents, emulsions, cleaning compounds, steam or

other similar materials and methods which involve a solvent or cleaning action.

SSPC-SP-2 or St 2

Hand Tool Cleaning - Removal of all rust scale, mill scale, loose rust and loose

paint to the degree specified by hand wire brushing, hand sanding, hand

scraping, hand chipping or other hand impact tods or by a combination of

these methods. The substrate should have a faint metallic sheen and also be free

of oil, grease, dust, soil, salts and other contaminants.

SSPC-SP-3 or St 3

Power Tool Cleaning - Removal of all rust scale, mill scale, loose paint, and loose

rust to the degree specified by power wire brushes, power impact tools, power

grinders, power sanders or by a combination of these methods. The substrate

should have a pronounced metallic sheen and also be free of oil, grease, dirt,

soil, salts and other contaminants. Surface should not be buffed or polished

smooth.

SSPC-SP-4

Flame Cleaning - Removal of all loose scale, rust and other detrimental foreign

matter by passing high temperature, high velocity oxy-acetylene flames over the

entire surface, followed by wire brushing. Surface should also be free of oil,

grease, dirt, soil, salts and other contaminants.

SSPC-SP-5 or Sa 3 or NACE 1

White Metal Blast Cleaning - Removal of all mill scale, rust, rust scale, paint or

foreign matter by the use of abrasives propelled through nozzles or by centrifugal

wheels. A White Metal Blast Cleaned Surface Finish is defined as a surface with a

gray-white, uniform metallic color, slightly roughened to form a suitable anchor

pattern for coatings. The surface, when viewed without magnification, shall be

free of all oil, grease, dirt, visible mill scale, rust, corrosion products, oxides, paint etc

SSPC-SP6 Sa 2 NACE 3

Commercial Blast Cleaning - Removal of mill scale, rust, rust scale, paint or

foreign matter by the use of abrasives propelled through nozzles or by centrifugal

wheels, to the degree specified. A Commercial Blast Cleaned Surface Finish is

defined as one from which all oil, grease, dirt, rust scale and foreign matter have

been completely removed from the surface and all rust, mill scale and old paint

have been completely removed except for slight shadows, streaks, or

discolorations caused by rust stain, mill scale oxides or slight, tight residues of

paint or coating that may remain; if the surface is pitted, slight residues of rust or

paint may by found in the bottom of pits; at least two-thirds of each square inch

of surface area shall be free of all visible residues and the remainder shall be

limited to the light discoloration, slight staining or tight residues mentioned

above.

SSPC-SP-7 or Sa 1

Brush-Off Blast Cleaning - Removal of loose mill scale, loose rust, and loose paint,

to the degree hereafter specified, by the impact of abrasives propelled through

nozzles or by centrifugal wheels. It is not intended that the surface shall be free of

all mill scale, rust, and paint. The remaining mill scale, rust, and paint should be

tight and the surface should be sufficiently abraded to provide good adhesion

and bonding of paint. A Brush-Off Blast Cleaned Surface Finish is defined as one

from which all oil, grease, dirt, rust scale, loose mill scale, loose rust and loose

paint or coatings are removed completely but tight mill scale and tightly

adhered rust, paint and coatings are permitted to remain provided that all mill

scale and rust have been exposed to the abrasive blast pattern sufficiently to

expose numerous flecks of the underlying metal fairly uniformly distributed over the

entire surface.

SSPC-SP-8

Pickling - Removal of all mill scale, rust and rust scale by chemical reaction, or by

electrolysis, or by both. It is intended that the pickled surface shall be completely

free of all scale, rust, and foreign matter. Furthermore, the surface shall be free of

unreacted or harmful acid or alkali, or smut.

SSPC-SP-9

Weathering Followed By Blast Cleaning - Weathering to remove all or part

of the mill scale followed by one of the blast cleaning standards.

SSPC-SP-10 or Sa 2-1/2 or NACE 2

Near-White Blast Cleaning - Removal of nearly all mill scale, rust, rust scale, paint,

or foreign matter by the use of abrasives propelled through nozzles or by

centrifugal wheels, to the degree hereafter specified. A Near-White Blast

Cleaned Surface Finish is defined as one from which all oil, grease, dirt, mill scale,

rust, corrosion products, oxides, paint or other foreign matter have been

completely removed from the surface except for very light shadows, very slight

streaks or slight discolorations caused by rust stain, mill scale oxides, or light, tight

residues of paint or coating that may remain. At least 95 percent of each square

inch of surface area shall be free of all visible residues, and the remainder shall

be limited to the light discoloration mentioned above.

SSPC-SP 11

Power Tool Cleaning to Bare Metal - Power tool cleaning to produce a bare

metal surface and to retain or produce a surface profile.

This specification is suitable where a roughened, clean, bare metal surface is

required, but where abrasive blasting is not feasible or permissible.

This specification differs from SSPC-SP 3, Power Tool Cleaning, in that SSPC-SP 3

requires only the removal of loosely adherent materials and does not require

producing or retaining a surface profile.

SURFACE PROFILE MEASUREMENT USING TEST-EX TAPE